SIS4000 SHAFT COMMUNICATION SYSTEMS

The SIS4000 is the latest generation shaft inspection system from GST, based on common principles from the advanced CCS3000 System and using modern synthesized frequency.

- Ideal for shaft Inspections

- Provides shaft communications, belling and emergency stop

- High power, high quality analogue audio channel (1.5W)

- Ease of installation and maintenance with the new wideband omni-coupler antenna design

- Synthesised system: no coil/cap/crystal changes

- Software driven (flash PIC’s used throughout for easy updating/modification of software)

- Relays for Belling/Carrier /Bell follower relays are rail-mounted

- Lock-bell function

- Can interface with IC4001 Intercom System (Optional Rail mounted interface module and 2 pin socket)

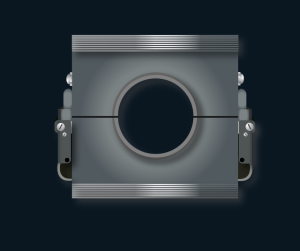

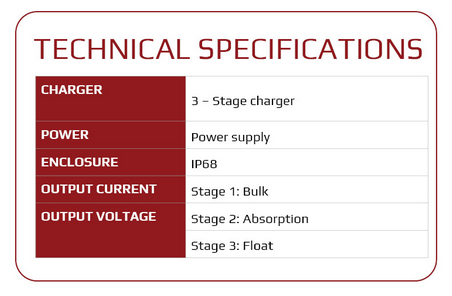

CBS3000 INDUCTIVE CHARGER

The batteries on the shaft conveyance are required to power the electronic equipment and must be changed on a regular basis.

This inconvenience initiated the design of the CBS3000 inductive charging system, which provided a high burst of energy during the short stops while off-loading. This energy top-up throughout the daily cycles keeps the battery charged.

- No physical contact between fixed and moving coils (Inductive technology)

- No mechanically wearing components.

3 – stage charging for optimal battery life and protection. - IP68 Rating.

- 12V

- Ease of Installation

- The system reduces maintenance and operational downtime

- Smaller capacity can be used. No mechanical wear and tear.

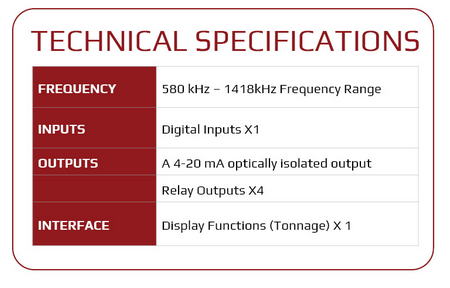

SMS3000 SHAFT COMMUNICATION SYSTEM

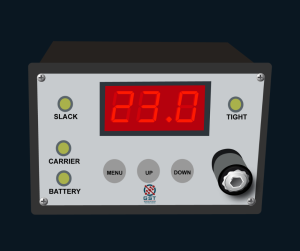

The SMS3000 Analog Shaft Monitoring System is used to monitor the weight of a conveyance in a shaft. Trip points are set in the monitor on surface to stop the winder engine when slack and tight rope conditions occur.

- The system can be used on man-cages to prevent overloading and as a safety device for slack and tight rope.

- When used on a skip, the tonnage can be recorded (by mine supplied system) to monitor the total amount of ore hoisted.

- No dead-spots in the shaft.

- The system is very compact and consists of a Transmitter/Battery Enclosure, Monitor/Receiver, optional PSU/UPS and L-Coupler antenna.

- Ten frequencies (channels) available.

- Low output power (into the coupler) of only 50mW.

- Low current consumption.

- 1 digital input to minitor doors, booms etc.

- A 4-20 mA optically isolated output.

- Slack, tight,carrier and digital output relays.

- Mass follower mode (enabled / disabled in firmware).

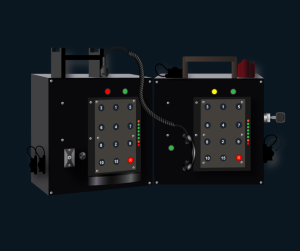

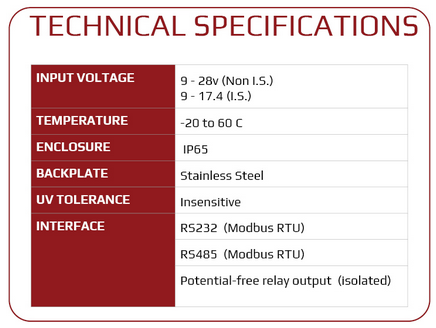

CCS3000 SHAFT COMMUNICATION SYSTEM

The CCS3000 radio is a real time communication system offering slack and tight rope monitoring functionality with warning alarms and trips to prevent the conveyance from going into a tight and slack condition. The good quality voice communication as well as belling to surface and back, is used for normal day to day as well as inspection usage. Using the available 56 digitals for interlocking of doors, booms and Levelok etc. – making the CCS3000 a comprehensive shaft communication and management tool.

- PAU (Parameter Adjustment Unit)

- Synthesized frequency selection

- Operator configurable

- Computer based parameter setting unit

- System setup and parameter settings done from surface

- Modules are interchangeable between shaft Systems

- Reduced stores holding

Options:

- Real time cage x – y Parameter Monitoring

(Vibration Monitoring) - Real time Dual Rope Equalization Monitoring

- Tight & Slack rope monitoring

- Voice communication between cage and surface

- Analog digital handling capability

- Shaft inspection

- Three segment LED display indicates tonnage of the cage

- Indications: Build in test equipment (B.I.T.E.)

- LED Indicators for Slack rope, Tight rope, Battery voltage

- Buzzer alarm and warning indication

- Fail Safe – System trips on loss of carrier signal and on other unsafe conditions

- Reset Function – Electronic coded key (Reset Key) for resetting system

- Supervisor

SMS4000 SHAFT COMMUNICATION SYSTEM

The SMS4000 Analog Shaft Monitoring System is used to monitor the digital inputs on a conveyance in a shaft. Digital inputs are useful to monitor whether cage doors are fully closed and whether poles are in place when conveying material cars. The system is also frequently used as a derailment tripping device on conveyances used in decline shafts.

- The PSA “proving” function monitors the actual sound from the siren, which is modulated to easily distinguish it from sounds with a similar frequency.

- Low power design

- Robust protection against lightning, spikes and surges.

- Pullkeys are hot swappable

- Plug ‘n play – minimize down time.

- HMI (option) situated in the controller for monitoring, setup and fault finding.

- Advanced system diagnostics to aid fault-finding

- Pullkeys are auto-addressing

- LED strobe on each Pullkey visually indicates PSA

- Pilot loop LED in each Pullkey confirms switch action in lockout

- Controller indicates Pilot status and PSA Proof status via two fail-safe relay contacts.

- Pilot module with automatic time-out for fault-finding (to prevent bridging out).

- Mechanical flag-arm to indicate lockout state.

- Loud distinctive sound pattern makes PSA audible above high background noise levels.

- Dedicated addresses available for third party products, such as belt tear, misalignment, etc.

- Pilot module with automatic time-out for ease of fault finding (to prevent bridging out of pullkeys)

- Several popular protocols are available for interfacing to the Controller.

- A list of PSA failures are stored in the controller.

- Existing IPS3000 systems can be upgraded to IPS3030.

Excellent quality and workmanship of their products. A wonderful team to work with.

Being 5-star rated signifies excellence at its finest

What our customers say

I love my work with Guduza.