DUST SENSOR

FIXED PARTICULATE MONITOR

Delivers precise, real-time airborn particulate measurements with robust design and intergrated alarms.

- Measuring Principle: Laser

scattering. - Operating Temperature: -10 to

+50°C. - Power Requirement: 14 to 24 VDC,

700 mA. - Dimensions: 120 x 120 x 80 mm.

- Weight: 350 g (without cabling).

- Data Storage: 512 MB SD card (max

size supported: 2 GB).

- Real-time Monitoring: Measures PM1,

PM2.5, PM4, and PM10 continuously

with a single device. - Laser Scatter Technology: Ensures

precise and reliable particle

measurement with 10% accuracy. - Data Storage: 512 MB SD card

reader (max size supported: 2 GB). - Real-time and TWA Values: Provides

both real-time monitoring and time-

weighted average values for all

particle sizes. - Large Colour Graphic LCD: On-

screen graphical display. - Audible and Colour-Coded Visual

Alarms: Programmable alarm

thresholds. - Durable Design: Housed in a robust

glass-filled polyester enclosure. - Continuous Operation: Designed for

24/7 monitoring.

- Dust-laden Activities: Suitable for

construction, mining, quarrying,

ports, and metallurgical processes. - Health and Safety: Our reliable tools

help authorities prevent serious

illnesses like pneumoconiosis and

silicosis by providing accurate data,

empowering proactive safety

measures. - MODBUS Interface: Supports

MODBUS RTU communication for

easy integration.

- Intrinsic Safety: Complies with SANS

(IEC) 60079-11:2012. - Regulatory Requirements: ARP

0108:2014. - Explosion Protection: Ex ia I Ma

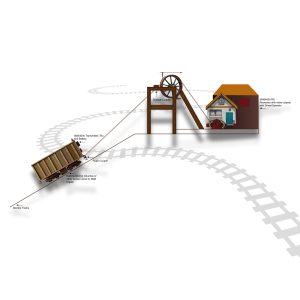

SMS DERAILMENT DEVICE

SEAMLESS SAFETY IN MOTION: RELIABLE CONNECTIVITY. ULTIMATE SAFETY.

Our derailment device ensures uninterrupted safety with real-time monertoring and immediate responce. No matter the track conditions.

- Detects Derailment: Inductive sensor

detects the metal rail, ensuring

continuous monitoring. - Tilt Detection: System digital signal

falls away if conveyance derails or

tilts away from the rail. - Immediate Response: Relay at

surface panel de-energises if the

sensor does not detect the rail,

providing an instant indication of

derailment.

- No Dead Spots: Continuous communication as long as the VRS coupler sees

the cable. - Direction Changes and Curves: System communication unaffected by changes

in track direction or curves. - Easy to Repair: Simplified maintenance and repairs due to the system design.

- Carrier Signal Relay: Energised relay indicates good signal; relay falls away

when the signal is lost.

- Communication via long wire antenna

or omni couplers. - Low frequency radio signal induced

into a cable running the length of the

track. - Coupler at headgear/winder induces

signal through cable. - Conveyance has a similar coupler

that transmits/receives signals into

the cable. - Couplers (VRS) are pointed at the

cable but not attached. - Induced signal acts as the data

carrier for digital data. - Steel wire rope used as antenna

cable, routed along the track. - Surface unit (SMS4000 Receiver)

placed at the driver’s cabin or similar

location. - Transmitter (SMS4000) placed on the

conveyance. - VRS couplers on both units to induce

the signal. - Inductive sensor used to detect metal

rail. - Sensor energises relay at surface

panel when rail is detected.

- Battery backup to preserve the integrity of the system in case of a power failure

- Default panel capable of controlling 5 smoke damper units. Expandable upon request.

- Industry standard 4- 20mA input from any environmental sensor

- Potential free relay outputs, fail to safe state.

- Display and keypad for local monitoring and configuration.

- Configurable warning level and warn delay when the environmental condition exceed the activation threshold.

- Configurable activation level and activation delay when the environmental condition exceed the activation threshold

- Automatic or manual control

- Done in accordance with the mine's fire risk assessment and simulations.

5 WAY DAMPER CONTROL PANEL

DETECTS DANGER AHEAD OF TIME, ENSURING SAFE EVACUATION.

In the case of fire or toxic gases, such as carbon monoxide, sulphur dioxide, or

smoke in the mine’s air intake, this can be detected at a pre-determined level and

automatically switch the ventilation louver (Smoke Damp), forcing the contaminated

air to be redirected to the return. This allows workers additional time to evacuate to

a safe location with less contaminated air.

- Automation Enabled Mining Ventilation Louver

- Galvanised Finish

- Light Weight

- Multi-functional Application

- Low leakage Seal Blades

- Cost effective

- Low maintenace

- Easy installation

- Battery backup to preserve the integrity of the system in case of a power failure

- Default panel capable of controlling 5 smoke damper units. Expandable upon request.

- Industry standard 4- 20mA input from any environmental sensor

- Potential free relay outputs, fail to safe state.

- Display and keypad for local monitoring and configuration.

- Configurable warning level and warn delay when the environmental condition exceed the activation threshold.

- Configurable activation level and activation delay when the environmental condition exceed the activation threshold

- Automatic or manual control

- Done in accordance with the mine's fire risk assessment and simulations.

AUREA BIO-WATCH

PERSOBNAL HEALTH AND ENVIRONMENTAL MONITOR.

The aurea bio-watch is a sophisticated device designed to ensure your safety by continuously both environmental and bio-metric paramaters.

- Essential for environments requiring

constant monitoring of both

environmental and personal health

parameters. - Provides real-time alerts for

deviations from safe levels. - Enables swift action in response to

potential hazards.

providing an instant indication of

derailment.

- Protected by an international patent

for its unique operation. - Continuously tracks both

environmental and biometric

parameters. - Main screen displays all

environmental parameters

simultaneously. - Biometric parameters accessible via

a menu. - Alarms are triggered for immediate

health threats. - Parameters exceeding preset

thresholds are shown on the main

screen with visual and vibrate alerts.

- Small and compact.

- Can be worn on the wrist or as a

badge (some features not available

as a badge). - Measures ambient temperature.

- Measures relative humidity.

- Measures barometric pressure.

- Calculates heat stress index, wet

bulb temperature, and dew point. - Measures up to 3 gases (flammable,

toxic, and VOCs). - Measures heart rate.

- Measures SpO2.

- Measures carboxyhaemoglobin levels

in blood. - Measures body temperature.

- Measures movement (can detect

freefall, impact, and others). - Data logging and downloading.

- Multi-colour LED alarm function with

vibrate alert. - Inductive charging.

- Wireless connectivity (BLE in first

release). - Messaging possible with network

coverage.

GOAFWARN

EARLY WARNING TECHNOLOGY.

The Goafwarn is a micro-eismic system that delivers real-time monitoring and warmings for mining roof instabilities, offering promnt risk feedback and storing data for future analysis.

- Timely Risk Detection: Offers real-

time processing of micro-seismic

data to detect risks promptly. - Versatile Application: Suitable for

monitoring goafing, fall-of-ground,

and other underground mining

instabilities. - Compliance and Safety: Ensures

certified operation and safety with

specified power input ranges and

Intrinsically Safe power supply

options.

- Real-time Monitoring and Processing:

Real-time monitoring provides

prompt risk feedback for instabilities

like goafing, fall-of-ground, and

collapses in mining. - Onboard Data Storage: Raw data is

stored onboard for post-analysis or

audit purposes - Power Supply Options: Supports two

power sources: internal battery packs

or an external 12V nominal

Intrinsically Safe supply. - Standard Profiles: Configurable for

various applications with standard

profiles for different sensor setups

and feature sets.

- Data Processing:

Real-time data processing to generate alarm outputs.

Data logging capabilities with configurable profiles for various applications - Communication Interface:

Serial communication interface available, typically for ModBus integration. - Power Supply:

Internal battery packs and external 12V nominal Intrinsically Safe supply.

Input range: 9V - 12.7V. - Environmental Specifications:

Operating temperature range: -20°C to +70°C. - Installation and Configuration:

Configurable via terminal commands or pre-loaded profiles.

BELL WINDER EVENT RECORDER

REAL-TIME MONITORING AND DETAILED EVENT RECORDING.

The recorder is designed as a single device to monitor actions, or “events”,

during shaft operations. It is PLC-based with a Human Machine Interface (HMI).

This functionality is crucial for monitoring events, near misses, and incidents,

providing a factual representation of what occurred. This makes it an excellent

tool for evaluating and recording safety events.

- Mass storage via SD card and/or

USB flash drive. - Real-time data monitoring and daily,

shift, or custom time-filtered hoist

reports. - Customisable shaft-specific codes for

signal interpretation. - Remote web page interface.

- Seven individual belling signal

channels. - Two quadrature encoder input

channels for winder velocity,

position, and trip count. - Twenty-four digital inputs for winder

control monitoring. - Data logging of all inputs for up to

one year. - Visual alarm indication with an alarm

list. - HMI interface.

- Ethernet communication, with

Ethernet/IP & Modbus available on

request. - User access control.

- Standalone system.

- Customisation and support per client

requests.

Excellent quality and workmanship of their products. A wonderful team to work with.

Being 5-star rated signifies excellence at its finest

What our customers say

I love my work with Guduza.